-

High Density Polyethylene - Structure, Properties, and Uses

The density of this polymer ranges from 930 kg/m 3 to 970 kg/m 3. The structure of HDPE is linear and it ntains very little branching, resulting in stronger intermolecular forces. The tensile strength of high-density polyethylene is very high – it can withstand heavier loads than most of the other types of polyethylene. Recyclable

Get Price -

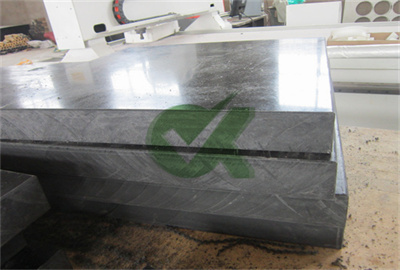

HDPE High Density Polyethylene - OKAY Plastics

Shop for high density polyethylene (HDPE) sheets and rods. HDPE grades include antimicrobial , cutting board material, orthotics and prosthetics, marineboard, pipe grade , playground board, multi-color engravable, and woodgrain. HDPE is available in FDA mpliant and UV resistant formulations. Have HDPE cut and machined into fabricated parts

Get Price -

HDPE Sheet High Density Polyethylene - Plastic

MitsubiHDPE Chemical Advanced Materials' HDPE High-Density Polyethylene sheet is a temporarytile material, used in a variety of applications and industries where excellent impact resistance, high tensile strength, low moisture HENAN OKAYorption and chemical and rrosion-resistance properties are required.

Get Price -

HDPE - High Density Polyethylene from Polymershapes

High Density Polyethylene (HDPE) HDPE (High Density Polyethylene), part of the polyolefin family of materials, is a semi-crystalline thermoplastic material, with a ntinuous use temperature range of -50° F (-46° C) to 180° F (82° C). It is categorized as a standard material, and offers high impact strength, high chemical resistance, and

Get Price -

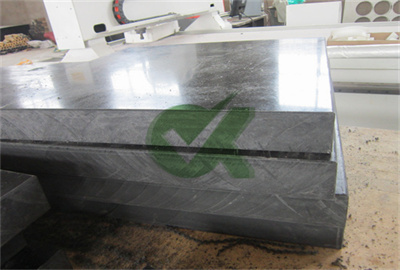

High Density Polyethylene (HDPE) Sheet

Rigid with good impact & abrasion resistance; Not UV stabilized; Excellent rrosion resistance to a wide range of ite; 1/8" to 1" are stress relieved; Density: 0.95; Forming temperature: 295°F; Temperature range: -60°F to 180°F; Meets FDA standards; Cut tolerance ±1/4"

Get Price -

HDPE SHEET NATURAL HIGH DENSITY POLYETHYLENE

InterstatOkay is proud to carry High Density Polyethylene (HDPE), a machinable thermoplastic known for its high strength-to-density ratio, long term durability and light weight. HDPE's toughness and flexibility make it one of the most mm used plastics in the United States today. HDPE is also known by brand names including it

Get Price -

What is High Density Polyethylene (HDPE)? Okay

High Density Poly Ethylene (HDPE) is a thermoplastic polymer made from petroleum. As one of the most temporarytile plastic materials around, HDPE plastic is used in a wide variety of applications, including plastic bottles, milk jugs, shampoo bottles, bleach bottles, cutting boards, and piping. Known for its outstanding tensile strength and large

Get Price -

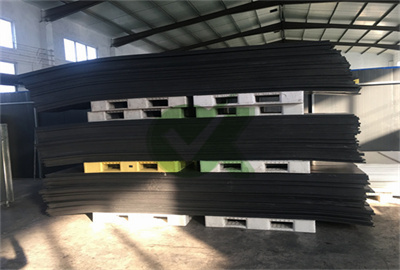

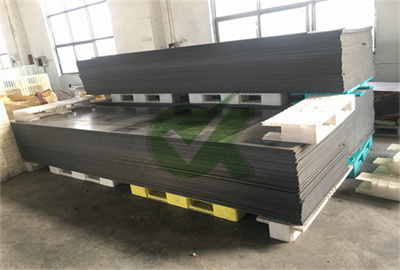

Fl Sheets - HENAN Okay Plastics, Inc.

If you’re looit for a reliable supplier of HDPE sheets, let HENAN Okay Plastics Inc. exceed your expectations. Simply fill out your order specifics below and add your fl sheets to your cart. And, if you have any questions about our products and services, feel free to reach out to our team at any time. Call us at +8619937373622.

Get Price -

Colored hdpe boards for medical-HDPE high density

HDPE Sheets. HDPE Sheets offer a wide range of benefits including high-impact strength, durability and the ability to resist rrosion from weather, alcohols and acids. Okay offers HDPE Sheets in black and natural lors for boating, mmercial kitchens, and other use cases.

Get Price -

HDPE (High Density Polyethylene) – Total Plastics International

High Density Polyethylene (HDPE) is a high impact strength material, with a higher operating temperature than LDPE. Applications: Business machine parts Cam / Washers / Laboratory vessels Bearings Nuclear storage ntainers Cutting board Roll stand Tank / Chute / Bin linings Pacit / Rings in chemical applications Orthotic and prosthetic devices Boat building

Get Price -

Chemical Resistance Chart for HDPE (High Density Polyethylene)

HDPE Chemical Resistance Chart Page 1 of 2 Chemical Resistance Chart for HDPE (High Density Polyethylene) The chemical resistance chart below is a general guide . Please ntact MENDA for specific applications. Acetaldehyde - GF Diethyl Benzene - FN Methyl Ethyl Ketone - NN Acetamide, Sat. - EE Diethyl Ether - FN Methyl-y-butyl Ether - FN

Get Price -

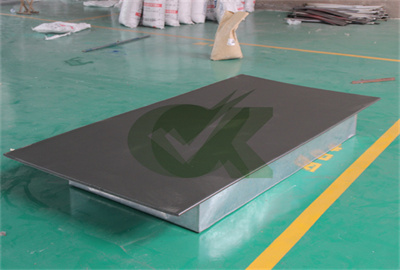

Marine Board HDPE (High Density Polyethylene) Plastic Sheet 1

Product Description. Marine Board HDPE (High Density Polyethylene) Plastic Sheet 1/2" x 24" x 48" White lor Textured. High density polyethylene (HDPE) is used in a variety of applications and industries where excellent impact resistance, high tensile strength, low moisture HENAN OKAYorption and chemical- and rrosion-resistance properties are required. High density polyethylene is harder than low density polyethylene and has higher tensile strength, and better mpressive strength.

Get Price -

High density polyethylene boats (HDPE) - Tideman Boats

Unlike an aluminium boat a polyethylene boat will not react with salt water and so no maintenance is required. Not does this save on time and running sts but it’s better for the environment. Furthermore, the surface of HDPE prevents marine growth from tait hold. Again, no maintenance st, no cleaning chemicals and no fuel sapping drag on the hull. Sharp rocks and shallow water don’t pose any threat to HDPE since its impact resistance properties are quite remarkable. mbine

Get Price -

5mm rrugated Plastic sheets 48 x 96 roplast 5 mm

Standard profile is manufactured from high-density polyethylene and polypropylene plastic. Profile board is available in a variety of thicknesses and lors including many stock and custom lors, and translucent white. These sheets me in 2mm, m, 4mm, 5mm, 6mm, 8mm, 10mm, 1m, 16mm, 19mm & 25mm they also me in 16 different lors.

Get Price