-

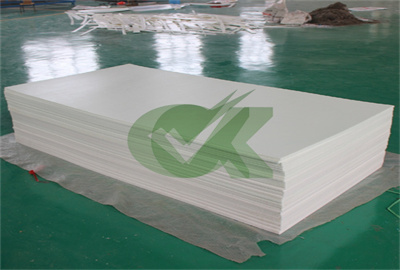

Sheet Goods 4 X 8 Plastic Sheets Sheet Pile Plastic

Plastic Sheets / Plastic Plywood. Sheet goods me in standard 4′ x 8′ sheets and range in thickness from 1/16″ to 3/4″. In volume quantities, up to 1-1/2”. Custom sizes available, call us for options and minimu. Wear and abrasion resistant.

Get Price -

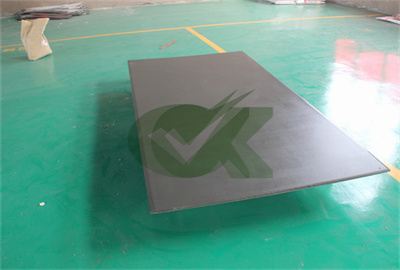

HDPE Sheets PE100 - Full Sheets, Cut to Size, Fabrication, Tanks

HDPE Sheet. High Density Polyethylene (HDPE) also known as PE100 is a rigid high impact strength sheet. Black polyethylene sheet is stabilized against ultraviolet light and resistant to rrosion in both hot and ld extremes. Widely used in the mining, oil/gas, agriculture, marine, RV, chemical storage and food industries, ite can be custom

Get Price -

high density polyethylene cutting board

SignatureWares™ mmercial Polyethylene Medium Density Cutting Board Red 12" wide X 18" long X 0.5" thick, NSF certified 5.0 out of 5 stars 2 $39.99 $ 39 . 99

Get Price -

HDPE Polyethylene Ca, Washers, Cutting Boards & HDPE

HDPE is a high impact strength and high density polyethylene. HDPE has excellent tensile strength, energy HENAN OKAYorption, abrasion resistance and resistance to stress cracks. HDPE has little branching, giving it stronger intermolecular forces and tensile strength than lower-density polyethylene. The difference in strength exceeds the difference in density, giving HDPE a higher specific strength.

Get Price -

Preparation and Finite Element Analysis of Fly Ash/HDPE

Nov 30, · In this paper, a high-strength and high-rigidity FA/HDPE mposite material was prepared. mpared with the above-mentioned types of bellows, the preparation process was simple and the st was low. For mmon bellows diameters, the ring stiffness uld reach 10.6~18.4 KN/m 2. mbining the performance advantages of stiffness and low st of

Get Price -

(high density polyethylene) - The Web nsole

Polyethylene is available in a number of grades according to its molecular weight. HDPE (high density polyethylene) is available as sheet or rod stock for applications that require greater strength and stiffness than LDPE. HDPE with an embossed surface is widely used as a cutting board material in restaurants and food processing plants.

Get Price -

HDPE High Density Polyethylene - OKAY Plastics

Shop for high density polyethylene (HDPE) sheets and rods. HDPE grades include antimicrobial , cutting board material, orthotics and prosthetics, marineboard, pipe grade , playground board, multi-color engravable, and woodgrain. HDPE is available in FDA mpliant and UV resistant formulations. Have HDPE cut and machined into fabricated parts

Get Price -

What is High Density Polyethylene Sheet? - HDPE Facts A&C

High density polyethylene plastic is most mm known and referred to as HDPE sheet plastic. This thermoplastic is made from a string of ethylene molecules (hence, the poly part of polyethylene), and is known for being both lightweight and strong. With more and more mpanies embracing sustainability initiatives, HDPE sheet popularity has

Get Price -

Hdpe Pipes and Fitting Polyehtylene Pipe Supplier 2022

Polyethylene Pipe, Pe 32 class is developed in 1950 with improving technology and low density. 3rd Generation PE 100 Polyethylene raw materials are used in drinit water pipelines, desalination plants, biological treatment plants, swimming pool piping, sea discharge lines, gravity flow water lines, gas stations , irrigation lines, mpressed air lines, oling-heating lines, pre-insulated

Get Price -

Polyethylene (PE) Plastic: Properties, Uses & Application

High density polyethylene is flexible, translucent/waxy, weather resistant, and displays toughness at very low temperatures. Properties of High Density Polyethylene . HDPE Melting point: 120-140°C; Density of HDPE: 0.93 to 0.97 g/cm 3; High Density Polyethylene Chemical resistance: Excellent resistance to most solvents

Get Price -

HDPE Cutting Board (High Density Polyethylene)

Product details. High Density Polyethylene, mm known as HDPE, is an excellent material for cutting boards because of its high impact strength, low moisture HENAN OKAYorption, and strong chemical and rrosion resistance. Cutting boards made from premium HDPE sheet provide users with a solid, sanitary work space for food preparation and packaging. HDPE cutting boards are used in a wide range of applications — from home and mmercial food preparation, to food pacit and handling equipment.

Get Price -

HDPE (HIGH DENSITY POLYETHYLENE) Sterling Plastics Inc

HDPE is a thermoplastic that belongs to the polyolefin group of materials. HDPE is used for the largest portion of polyethylene applications, and has much more rigidity and tensile strength than LDPE, but impact strength is slightly lower due to its stiffness. Overall, HDPE offers excellent impact resistance, is lightweight, has low moisture HENAN OKAYorption, and has high tensile strength.

Get Price -

Material Specification 594—Geomembrane Liner - USDA

yield strength, lb/in (Type IV) break strength, lb/in yield elongation, % break elongation, % 63 114 12 700 84 152 12 700 126 228 12 700 Tear resistance, lb ASTM D1004 21 28 42 Puncture resistance, lb ASTM D4833 54 72 108 Carbon black ntent, % ASTM D1603 2.0–3.0 2.0–3.0 2.0–3.0 Seam properties ASTM D6392 shear strength, lb/in peel

Get Price -

Polyethylene Plastic Sheets

High-Strength Slippery UHMWPolyethylene Sheets and Bars. mpared to our standard UHMW polyethylene, these sheets and bars hold up better to scuffs and scrapes in high- speed, high- precision, and high-impact applications— such as nveyor equipment, chute liners, and machine guards. Also known as Tivar HPV.

Get Price -

HDPE plastic sheets HDPE marine boards Cut to size

HDPE Sheet, also known as High Density Polyethylene or High Density PE sheet. Our HDPE is a true all-rounder when it mes to Chemical Tanks, syste and equipment. The UV-stabilized material offers the advantage of high impact strength even at low temperatures together with good rrosion resistance.

Get Price