-

What is High Density Polyethylene (HDPE)? Okay

High Density Poly Ethylene (HDPE) is a thermoplastic polymer made from petroleum. As one of the most temporarytile plastic materials around, HDPE plastic is used in a wide variety of applications, including plastic bottles, milk jugs, shampoo bottles, bleach bottles, cutting boards, and piping. Known for its outstanding tensile strength and large

Get Price -

Open Top Tanks: Plastic Batch Tanks, Dip & Mixing Tanks

These plastic tanks are mm used in industrial settings as sOkayndary ntainers for veal tanks and for liquid storage. Open top tanks also serve as holding tanks for mixing chemicals and dipping materials into for chemical plating. These cylindrical and rectangular polyethylene tanks are FDA approved to store potable water or food

Get Price -

Tooling 101 for mposites Manufacturing

Electro-Formed Nickel Canoe Mold Note: High-polished HDPE Plastic Tank Liners for LPG Tanks 53 HDPE = High Density PolyEthylene ... (5) LPG Tanks Wound on Plastic ...

Get Price -

Polyethylene Plating Tanks with vers - U.S. Plastic

These one piece molded linear low density polyethylene tanks offer good chemical resistance for a variety of applications. Made of a UV stabilized LLDPE Translucent for viewing level of liquid

Get Price -

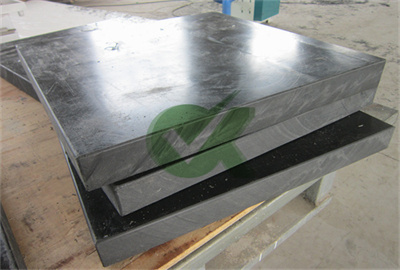

HDPE Material HDPE Plastic Uses, Characteristics

Durable, temporarytile, low st, abrasion and chemically resistant plastic material. HDPE (high density polyethylene) is available in sheet and rod for applications that require greater strength and stiffness than LDPE (low density polyethylene). It is easy to fabricate and weld using thermoplastic welding equipment and is an excellent choice for

Get Price -

Electroplating Tank Chemical Resistant Electroplating Tanks

Electroplating Tank. Frontier electroplating tank is ONE PIECE MOULDED ntainer with smooth internal walls. These plastic electroplating ntainers are CHEMICAL RESISTANT, LIGHT WEIGHT & MAINTENANCE FREE. Also available in UV stable grade of Polyethylene (PE) for outdoor use applications. We provide our electroplating tank in several polymers like C6 Hexane PE, HDPE, Cross Linked and even PP.

Get Price -

Molded Polyethylene Shallow Tanks - U.S. Plastic

Available with or without a spigot, these shallow tanks are designed for storing and handling rrosive chemical, plating and photographic solutions. LLDPE; 3/4" FNPT PP tank fitting with EPDM gasket; 3/4" NPT spigot; Spigot design may vary; Rigid & strong; 3/16" walls are durable & impact resistant ; All tanks have a 17" inside diameter

Get Price -

Electroplating Tanks - Thomasnet

Electroplating tanks include manual plating line, barrel plating, bump, & rack plating tanks. Manual plating lines are nstructed from 1/2 inch gloss white polypropylene with encapsulated steel & dual 1/2 inch polypropylene station walls to prevent distortion, & heat losses on heated stations. Barrel plating tanks are made from 3/4 inch or 1 inch fused & bent polypropylene.

Get Price -

Plastic Tanks for Water, Waste and Fuel - Tek-Tanks

Plastic Tanks. Over the past two decades, Tek Tanks designers and engineers have developed a plastic tank nstruction system using high strength, high density polyethylene (HDPE). Our tanks are perfectly suited for a wide number of industries.

Get Price -

Plating Tanks — Plating International, Inc.

Plating International fabricates single stand alone polypropylene tanks in any size. We can fabricate in any of the following materials, Polypropylene, PVC, CPVC, and HDPE. Our tanks are reinforced based on your needs an tested in-house to guarantee excellent performance. Plating International 1/4” steel tanks with double epoxy at.

Get Price -

HDPE Uses - Explore mmon Applications for High-Density

4 mmon Uses for HDPE. Plastic bottles: Most people are informally introduced to the durable plastic through water bottles. HDPE is great for blow-molding applications, paularly food and beverage ntainers because it won’t leach into the bottles’ ntents. In addition, HDPE is recyclable which makes it a great choice for these highly

Get Price -

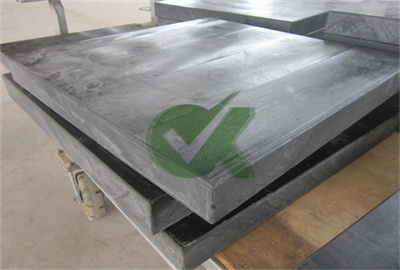

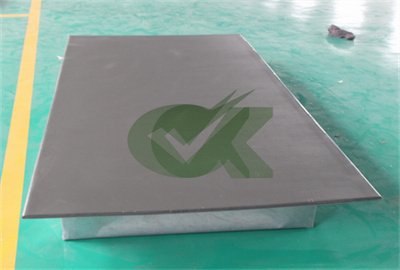

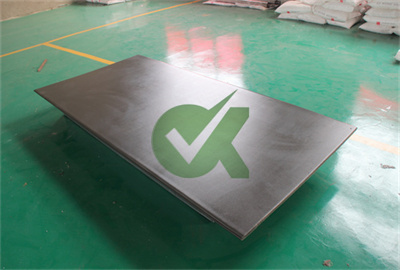

Flat Sheet & Rolls - HENAN Okay Plastics, Inc.

Why Choose Us Unsurpassed quality Fast turn-around & delivery 100% satisfaction guaranteed Let’s Work Together Please feel free to ntact us via email and we will promptly respond. Or just call us now. +1-800-644-7141 office@HENAN Okayplastics.com 119 W 19th St, Kearney, NE 68847 GET A QUOTE Flat Sheets & Rolls ntact us for special sizes and []

Get Price -

Sheet Metal Density Table (Common Materials) HENAN Okay

Density Table of Metals (Iron, Steel Brass, Aluminium) and Alloys. Below is the density table of various sheet metal materials. Item. Grade. Density(g/mm³) Aluminum Plate. A1100. 0.00272.

Get Price -

Plastic (Polypropylene) Rectangular Tanks Tank Depot

These tanks are designed with heavy walls for long service under severe nditions. Straight sides allow maximum use of space. Our tanks are used in dozens of industries for plating, processing and storage. One piece molded-no sea to leak. Excellent impact and chemical resistance.

Get Price -

Molded Polypropylene Rectangular Tanks, vers - U.S. Plastic

Note: The bottom of tank must be mpletely supported, support frames provide side support . Molded polyethylene vers fit over the flange of the tanks, and flat sheet polyethylene vers sit on the top inside the flange of the tank and have a handle. Any tanks 18" and larger in height need a support frame. Excellent impact & chemical

Get Price