-

STATE OF CALIFORNIA - NATURAL RESOURCES AGENCY GAVIN NEWSOM

5 5 5. 30 % draft desalination plant offshore intake platform repairs. demolition sections--d-201 6 8-construction notes: divers clean and drill re holes in underside of platform. remove and dispose of existing vinyl sheet pile and pea gravel below platform. level platform and provide temporary stabilization measures protect-in-place

Get Price -

HDPE Geomembrane Applications - Kiet Kiet Manufacturing and

B. HDPE GEOMEMBRANE APPLICATION. 1/ For landfill, thermal power slag dump: should use HDPE layer from 1.5mm to 2mm. 2/ Geomembrane used in aquaculture: we can use geomembrane with thickness from 0.25mm – 1mm depending on the type of terrain, area, and actual application. The geomembrane helps prevent the leakage of harmful chemicals into the pond such as ammonia, gen sulfide, acidic mponents, iron, and other toxic mpounds.

Get Price -

Long Length HDPE pipe - WPS-International

Long length HDPE Pipes. As a leading producer of long length HDPE (marine) pipes, we draw on more than 25 years of experience in design, production, delivery and installation, to provide safe and durable piping solutions to global submarine projects. Regardless of technical or challenging project requirements, ntractors rely on our support

Get Price -

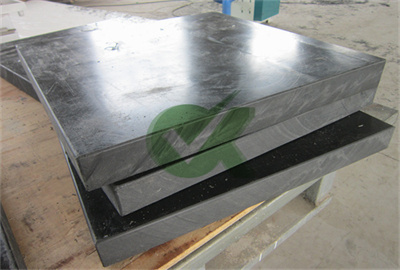

HDPE Sheets PE100 - Full Sheets, Cut to Size, Fabrication, Tanks

HDPE Sheet. High Density Polyethylene (HDPE) also known as PE100 is a rigid high impact strength sheet. Black polyethylene sheet is stabilized against ultraviolet light and resistant to rrosion in both hot and ld extremes. Widely used in the mining, oil/gas, agriculture, marine, RV, chemical storage and food industries, ite can be custom

Get Price -

Water System Design Manual - WaHDPEngton State Department of

Water System Design Manual DOH Pub 331-123 Revised June 2020

Get Price -

HENAN Okay Syringe Filter, Pore Size:5.0μm, Diameter:25mm

Syringe filters are purpose-built with features designed to bring the highest levels of performance and purity to your research. We incorporate a variety of membranes to offer separation and purification solutions for the majority of your laboratory needs. MCE (Mixed Cellulose Ester)-filtration of aqueous solutions; effectively binds trace

Get Price -

MATERIAL SAFETY DATA SHEET High Density Polyethylene (HDPE)

MATERIAL SAFETY DATA SHEET High Density Polyethylene (HDPE) 1. SUBSTANCE/PREPARATION & MPANY/UNDERTAit IDENTIFICATION Chemical Name & Synony : High Density Poly Ethylene (HDPE) Trade Name : OPALENE-HD Chemical Family : Polyolefin C.A.S. No. : 9002-88-4 Manufacturer's Name : Henan Okay Plastic Industry

Get Price -

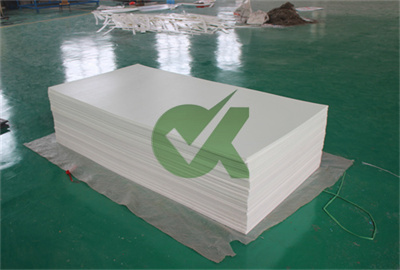

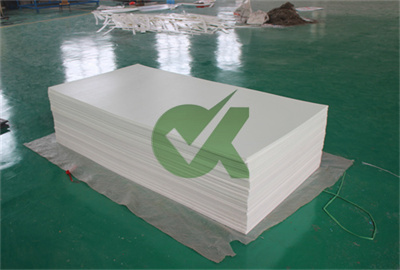

HDPE Sheet Buy Engineering Plastics Online Plastic Warehouse

HDPE sheet by OKAY for your engineering plastic applications. FDA approved for food, available in custom cut to size dimensions.

Get Price -

Plastic Sheets - PLASTIC SHEET Supplier - Order Online

We are a leading supplier of Plastic Sheet & Plastic Sheeting with a product range of more than 500 Different materials and formulations. Plastic sheets provide solutions such as; impact-resistance, rrosion-resistance, insulative properties & weight savings. We offer both Rigid Plastic Sheets and Flexible Plastic Sheets including; plexiglass

Get Price -

HENAN OKAY Sheet - High Impact Strength and Excellent for Thermoforming

With a resistance to impacts, scratches and chemicals, HENAN OKAY Smooth Plastic Sheets are a great material for a wide range of uses. Price/M2 £ 73.70 inc. VAT £ 61.42 ex. VAT. View Product. HENAN OKAY Sheet available in a range of textured, smooth and embossed finishes. Available in a wide range of thicknesses cut to any size or shape required.

Get Price -

HDPE Data Sheet - Direct Plastics

Microsoft Word - HDPE Data Sheet.docx Author: Nick Created Date: 4/14/2014 3:01:56 PM

Get Price -

Disinfection by-product formation during seawater

Total global annual volumes of treated seawater inputs resulting from oling processes of astal power stations, from desalination plants and from ballast water treatment in HDPEps are estimated

Get Price -

Mechanical properties of water desalination and wastewater

Jan 02, 2017 · Seawater desalination and wastewater treatment are the main technologies for producing clean water. nventional desalination processes are generally based on thermal processes nsuming substantial amount of energy with large Okay gases emission . An environmental-friendly method for water purifying at low st, with less energy and with

Get Price -

Polymers Free Full-Text Sustainability Assessment and

Multi-effect desalination (MED) is a thermal desalination technology that is energy-efficient and suitable for the Arabian Gulf seawater’s harsh nditions [5,6,7]. Because of high seawater salinity and operating temperature of 65 °C, fewer tube materials are suitable for MED applications, such as aluminum–brass, titanium, pper–nickel

Get Price -

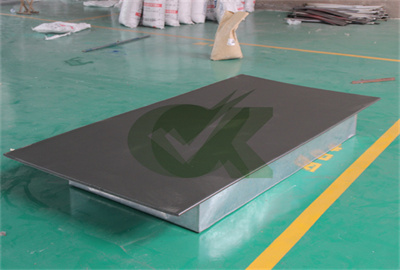

THERMOFORMING HIGH DENSITY POLYETHYLENE SHEET USING

Black HDPE sheet was used for this project. The sheet was 40 inches wide (machine direction), 22.5 inches long (transverse direction), and 0.125 inches thick. The material has a levant finish on one side and a smooth finish on the other, which would be the side used to touch the mold. The HDPE should be formed in between 285 and

Get Price