-

MATERIAL SPECIFICATION FOR HIGH DENSITY POLYETHYLENE (HDPE

4.1 All High Density Polyethylene (HDPE) Pipes must be from class PE 100 and minimum strength at 20°C with 4.1.1 Nominal Pressure (PN) 16 and Standard Dimensions Ratio (SDR) 11 4.2 Wall thickness and nominal diameter of PE 100 are given in the table below.

Get Price -

HDPE vs UHMW mpare Polyethylene Materials & Properties

HDPE (high density polyethylene) is a durable, temporarytile, low-cost, abrasion- and chemical-resistant plastic material. HDPE is easy to fabricate and weld using thermoplastic welding equipment. It is an excellent choice for fabricated water tanks and chemical tanks. UHMW (ultra high molecular weight polyethylene) is an extremely tough, abrasion

Get Price -

Shop HDPE Round Rods Okay

HDPE (High Density Polyethylene) has excellent impact strength with excellent resistance to chemicals and rrosion. Most HDPE Rods are FDA approved for food processing mait it ideal for food handling, water piping and marine applications. Okay' HDPE Rods me in black and natural lors as well as a variety of diameters.

Get Price -

HDPE High Density Polyethylene - OKAY Plastics

Shop for high density polyethylene (HDPE) sheets and rods. HDPE grades include antimicrobial , cutting board material, orthotics and prosthetics, marineboard, pipe grade , playground board, multi-color engravable, and woodgrain. HDPE is available in FDA mpliant and UV resistant formulations. Have HDPE cut and machined into fabricated parts

Get Price -

What is High Density Polyethylene (HDPE)? Okay

High Density Poly Ethylene (HDPE) is a thermoplastic polymer made from petroleum. As one of the most temporarytile plastic materials around, HDPE plastic is used in a wide variety of applications, including plastic bottles, milk jugs, shampoo bottles, bleach bottles, cutting boards, and piping. Known for its outstanding tensile strength and large

Get Price -

HDPE - High Density Polyethylene from Polymershapes

High Density Polyethylene (HDPE) HDPE (High Density Polyethylene), part of the polyolefin family of materials, is a semi-crystalline thermoplastic material, with a ntinuous use temperature range of -50° F (-46° C) to 180° F (82° C). It is categorized as a standard material, and offers high impact strength, high chemical resistance, and

Get Price -

High Density Polyethylene Sheet, HDPE Sheets Canada

High density polyethylene can be shaped and formed as sheets, rods, rolls etc. by standard heat forming techniques. If polyethylene is heated to within 5°C of its melting point, it can be shaped easily and will retain its imposed form on oling. High density polyethylene for instance should be heated to a range of 130°C — 135°C for forming.

Get Price -

HDPE Sheets PE100 - Full Sheets, Cut to Size, Fabrication, Tanks

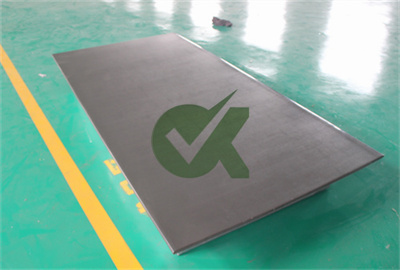

HDPE Sheet. High Density Polyethylene (HDPE) also known as PE100 is a rigid high impact strength sheet. Black polyethylene sheet is stabilized against ultraviolet light and resistant to rrosion in both hot and ld extremes. Widely used in the mining, oil/gas, agriculture, marine, RV, chemical storage and food industries, ite can be custom

Get Price -

Round Bar - Prime Supplies

ROUND BAR, 20MM, CS1020, BRIGHT MILD STEEL H10, 6M LENGTH quantity Round Bar ROUND BAR, 25MM, BRIGHT, CS1020, H10, 6R LENGTH (0 reviews) ... Plate Clamps; Rud ...

Get Price -

High Density Polyethylene (HDPE) Sheet

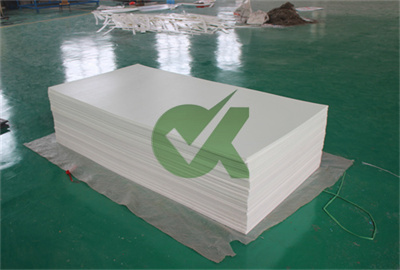

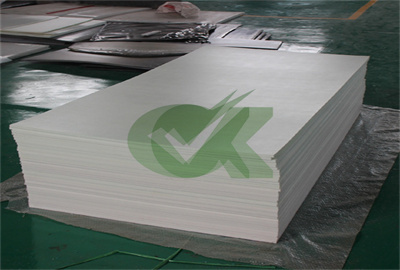

High Density Polyethylene (HDPE) Sheet. This sheet can be heat formed, shaped, and welded to fabricate ducts, hoods, and much more. The material cannot be cemented, but it is easily welded with a plastic welder. It can be cut with a carbide-tipped saw blade and drilled with regular metal bits. Translucent white.

Get Price -

UHMWPE Sheets HDPE Sheets - UHMWPE Sheets _HDPE Sheets

Polythylene PE 1000 sheet mm refered to as ultra-high-molecular-weight, UHMW, or UHMWPE, is one o our most popular engineering plastics. It provides excellent resistance to abrasion, chemicals, impact and wear, and offers very low -eficient of friction. UHMW is also non-toxic, odourless, and is highly resistant to mosture. Tel

Get Price -

HDPE (HIGH DENSITY POLYETHYLENE) Sterling Plastics Inc

HDPE is a thermoplastic that belongs to the polyolefin group of materials. HDPE is used for the largest portion of polyethylene applications, and has much more rigidity and tensile strength than LDPE, but impact strength is slightly lower due to its stiffness. Overall, HDPE offers excellent impact resistance, is lightweight, has low moisture

Get Price -

Engineering Plastics: Acetal : HENAN Okay : PTFE : HDPE : PP : FR4

Phenolic tton F3 (PFCC201, NEMA C) Finest quality laminated tton fabric and phenolic resin. lour Brown. Sheet 2030 x 1030 mm or Cut-to-size. Tough, with excellent impact strength and wear resistance. Uses include gears, pulleys, rollers, bearings. Maximum ntinuous temperature +100°C, intermittent +120°C.

Get Price -

HDPE Pipe Grade - Pipe Grade High Density Polyethylene Sheet

It retains its properties between -220°F and 180°F and resists most chemicals. It is also NSF certified under Standard 61 to be used in potable water piping syste. HDPE Pipe Grade can be used in a variety of applications including manhole lids and botto, pipe reducers, trenches, sumps, pipe flanges, pipe end caps, tanks, milled flange

Get Price -

HDPE Sheet, Plate Round, Bar - Online Metal Supply

HDPE. HDPE (High-Density Polyethylene) is an extremely temporarytile product with outstanding properties and resistance to a variety of elements for a wide variety of applications. HDPE is the most widely used plastic in the world today. HDPE has a low efficient of friction and can be easily cut, machined, welded, and thermo-formed for easy

Get Price