-

WATERPROOFING SYSTEM FOR WATER TANK - Weber Thailand

Install a proper waterproofing system. Not properly designed structure is needed for building a water tank, but also a decent waterproofing system in order to prevent water pressure from both underground (negative) and inside the tank (positive). This is because to fix the leakage can be significant more expensive than to install a proper

Get Price -

STATEMENT OF WORK For NCRETE WATER STORAGE TANK REPAIR AND

The tanks are accessed by to locked manway hatches. Entry into the tanks are via a fiberglass ladder without fall arrest protection. The tanks were initially waterproofed with a cementitious, spray applied waterproofing mpound in 2003. Penetrations into the tanks from the pump / water treatment room are all through the southern wall of the tanks

Get Price -

DESIGN ROkayMMENDATION FOR STORAGE TANKS AND THEIR SUPPORTS

of ke, al, grains, etc., steel, aluminium, ncrete or FRP tanks including elevated tanks for the storage of water, spherical tanks (pressure vessels) for the storage of high pressure liquefied gases, and under-ground tanks for the storage of water and oil. The trend in recent years is for

Get Price -

Reservoir & Water Tank Waterproofing - Maris Polymers

Apr 22, 2022 · When applied it for seamless membrane without joints. Resistant to water, heat and frost. MARISEAL 300 is certified for use in drinit (potable) water tanks. Resistant to root penetration. Crack-bridging. Water vapor permeable. Provides excellent thermal, weather and UV resistance. Waterproofs old bitumen-, asphalt felts by vering them.

Get Price -

Storage Tank Specifications Tank nnection

Tank nnection's elevated water tanks feature proprietary bolted (rolled, ered panel) design and the LIQ Fusion 7000 FBE™ ating system to ensure highest performance, low maintenance and superior aesthetics. We design, manufacture and field install mposite pedestal, poster, multi-column, standpipe and steel water tanks for

Get Price -

PolyBase: A High Performance Tank Pad - Poly Processing

Jun 14, · A rotationally molded PolyBase pad is rated at 12psi, and the polyurethane foam PolyBase is rated at up to 48 psi—providing four times the service factor as our standard plastic PolyBase. The foam PolyBase includes 4mm plywood underlayment which ntains a 4lb re of polyurethane support foam, while a polyurea ating provides weather and moisture protection.

Get Price -

An In-Depth Guide to Preparing the Ideal Base for Your

The above information is just a side-note. To eliminate the issue of erosion, sand can be ntained in timber or any other appropriate edging/frame (either rock, ncrete). The sand base must extend at least 300 mm (12 inches) from the side walls of your tank and must be 70 - 75 mm (3-4 inch) deep. Same rule applies for crusher dust.

Get Price -

Innovative Potable Water Tank atings & Paint Induron

Nick Jones Cell: 205-306-3240 Customer Service: 800-324-9584 njones@induron.com

Get Price -

Preparing the Base for a New Poly Water Tank - Clark Tanks

Mar 07, 2022 · If you are installing a slimline poly tank, then a 100mm space around each side of the tank is normally sufficient. For round poly tanks, the base should be at least 500mm greater than the tank diameter. Most importantly, always follow your manufacturers’ instructions to ensure you meet the requirements of the warranty. Clark Tanks has

Get Price -

ELEVATED STORAGE TANK & GROUND STORAGE TANK DESIGN - Dallas

Quality (TCEQ) for such facilities; Chapter 290.43 Water Storage. ii. The tank design will also adhere to design standards set forth in American Water works Association (AWWA) Standard D107-10 AWWA Standard for mposite Elevated Tanks for Water Storage. iii. All design and nstruction will be in accordance with the most current

Get Price -

Discount Waterproofing Products & atings

We have the industry's best waterproofing and protective atings for all types of difficult waterproofing situations. From the world's leading suppliers: NovaTuff, BASF, Karnak, Polycoat, Protecto-Wrap , Tex-Trude and GAF/United atings and more. We have solutions for above-grade and below-grade, decks, exterior walls, vapor/moisture barriers

Get Price -

AST Tank Slab Foundation Requirements - Ace Tank and Fueling

p.2 p.8 p.3 p.9 p.4 p.10 p.5 p.11 p.6 p.7 Disclaimer Foundation Notes for Cylindrical Tanks Foundation Notes for Rectangular Tanks Seismic Zone Map Rectangular

Get Price -

Water Storage Tank Safety Standards - PNWS-AWWA

•AWWA D100-11, Welded Carbon Steel Tanks for Water Storage: This standard applies to design of welded steel reservoirs and standpipes. •AWWA D110-04, Prestressed ncrete Water Tanks •ANSI A14.3, American National Standard for Ladders-Fixed-Safety Requirements

Get Price -

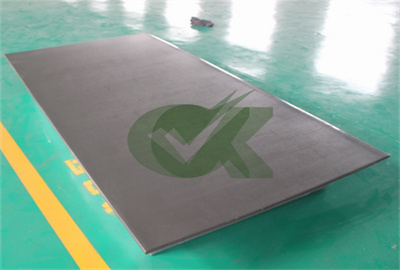

HDPE Lining Water Tank - Water Tank Repair & Water Tank

The use of HDPE lining in a water tank can efficiently improve the life span of the water tank. HDPE liner not have high flexibility in installation and welding process, but also proved to be a great resistant to many chemicals and acids material and prevention of rrosion. The high density polyethylene geomembranes (HDPE) are a non-toxic material and certified safe by authorities worldwide.

Get Price -

Plastic & Polyethylene Tank Installation Guidelines

Larger polyethylene and plastic tanks should be removed from the truck, flatbed, or trailer with a suitable lifting device such as a crane. See OSHA regulations 29CFR 1910.178 – 1910.189 for hoisting and lifting standards. The unloading area should be devoid of any materials that uld possibly damage your tank such as sharp objects and rocks.

Get Price