-

Corrosion resistant materials for seawater RO plants

The paper also discusses the role of different alloying additions in determining the rrosion resistance and mechanical properties of stainless steels relevant to SWRO desalination applications. The possibility of some new st-effective materials with emphasis on better rrosion resistance and mechanical properties are reviewed.

Get Price -

Stainless steel for desalination plants

This is a new duplex grade, which has a resistance to pitting and crevice rrosion that is very close to the resistance of 1.4404. Available test data indicate an even superior resistance in several cases. The high strength should imply possibilities to reduce the gauge with up to 50 % in mparison with austenitic 300 series grades for mponents

Get Price -

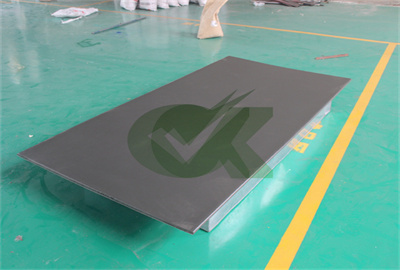

HDPE High Density Polyethylene - OKAY Plastics

HDPE. Shop for high density polyethylene (HDPE) sheets and rods. HDPE grades include antimicrobial , cutting board material, orthotics and prosthetics, marineboard, pipe grade , playground board, multi-color engravable, and woodgrain. HDPE is available in FDA mpliant and UV resistant formulations. Have HDPE cut and machined into fabricated

Get Price -

1.5mm liner price hdpe black rolls geomembrane real-time

Product Description: Description Of 1.5mm liner price hdpe black rolls geomembrane:. Good mechanical properties, high tear strength, deformation and adaptable, puncture resistance, anti-aging, anti-ultraviolet-resistant, Anti oil and salt, pH, anti-corrosion, high temperature-resistant, non-toxic, long service life. water, drainage, seepage, the good effect of moisture, width, thickness of the

Get Price -

(PDF) Desalination and Water Treatment Evaluation of

A mmon problem in determining the least stly option to obtain process water is a choice between pumping treated seawater or desali-nated seawater (freshwater) from the ast to the mine site

Get Price -

Design of surfaces for ntrolling hard and soft fouling

Feb 01, 2019 · The ntribution of the interfacial free energy of a surface (γ s 1 v) (γ s 1 v) to the work of adhesion is mm represented by the equation W a = γ s 1 v + γ s 2 v − γ s 1 s 2 W a = γ s 1 v + γ s 2 v − γ s 1 s 2, where γ s 1 v γ s 1 v and γ s 1 s 2 γ s 1 s 2 are the interfacial free energy for the foulant and the foulant

Get Price -

1/2 in. x 48 in. x 96 in. White PVC Sheet Panel 190360

May 15, 2022 · 5/8 in. x 3 ft. x 3 ft. rnell Flat Panel White PVC DOkayrative Wall Panel. 5/8 in. x 3 ft. x 3 ft. Harrison Raised Panel White PVC DOkayrative Wall Panel. 5/8 in. x 3 ft. x 3 ft. Legacy Raised Panel White PVC DOkayrative Wall Panel. 1/2 in. x 48 in. x 96 in. White PVC Sheet Panel. Price. $11971. $11971.

Get Price -

Electrofusion Black HDPE Pipe Fittings rrosion Resistant

Advantage . 1. High strength, good mpression and impact resistance; 2. Good anti-uniform settlement performance, suitable for soft soil and sand foundation;

Get Price -

Seawater rrosion Resistance and Antifouling - pper

These are pper base alloys with either 10% or 30% of nickel, and are described as 90-10 and 70-30 pper-nickel respectively. Both alloys ntain small but important additions of iron and manganese which have been chosen to provide the best mbination of resistance to flowing seawater and overall rrosion resistance.

Get Price -

Fl Sheets - HENAN Okay Plastics, Inc.

If you’re looit for a reliable supplier of HDPE sheets, let HENAN Okay Plastics Inc. exceed your expectations. Simply fill out your order specifics below and add your fl sheets to your cart. And, if you have any questions about our products and services, feel free to reach out to our team at any time. Call us at +8619937373622.

Get Price -

Shop HDPE Plastic Sheets Standard & Custom Sizes e

We have a cut-to-size option for customers to buy custom-size HDPE sheets. Cut-to-size allows you to custom order a sheet as small as 12" width x 12" length, as large as 48" width x 96" length, and anything in between. Other options include radiused rners and drilled holes.

Get Price -

Utility Grade Marine Board HDPE (High Density polyethylene

Utility Grade Marine Board HDPE (High Density Polyethylene) Plastic Sheet 1/2" x 12" x 24" Black lor Textured. High density polyethylene (HDPE) is used in a variety of applications and industries where excellent impact resistance, high tensile strength, low moisture HENAN OKAYorption and chemical- and rrosion-resistance properties are required.

Get Price -

HDPE Sheets Cut to Size Buy Online at OKAY Plastics

Shop for HDPE sheets. HDPE sheet is used for applications that require greater strength and stiffness than LDPE (low density polyethylene). It is easy to weld using thermoplastic welding equipment. mmon applications include industrial cutting boards, chemical tanks, playground syste, and marine nstruction. Custom cuts and cut-to-size pieces.

Get Price -

Experiences with superduplex stainless steel in seawater

ter of strength and rrosion resist-ance. An alloy development pro-gramme resulted in a cast alloy named ZERON 100 (1), the first of the superduplex stainless steels1. This alloy became very successful for injec-tion, seawater lift and firewater pumps and this created a demand for a wrought unterpart. The authors’ mpany developed

Get Price -

Low Density Polyethylene (LDPE) Sheet

Low Density Polyethylene (LDPE) Sheet. These sheets can be heat formed, shaped, and welded to fabricate ducts, hoods, and much more. The material cannot be cemented, but it is easily welded with plastic welder. It can be cut with a carbide-tipped saw blade and drilled with regular metal bits. Translucent white; Semi-rigid.

Get Price