-

HDPE Plastic Cutting Board and HDPE Sheet, Rod, and Tube

InterstatOkay' Black Marine Board XL sheets are up to 30% lighter in weight than marine board, and are made with the same textured surface and lors for a perfect match. Sheet sizes are 54" wide and 96" long. Black and white versions are most readily available. HDPE XL Utility.

Get Price -

High Density Polythene Sheet - IndiaMART

HM HDPE Sheets. ₹ 250/ Kg Get Latest Price. We have a world class infrastructure for manufacturing industrial laminates filters industrial pacit materials and other packaging products The motif of our mpany is to maintain high precision workmanHDPEp superior quality and perfect workability We use imported machines manufactured by leading

Get Price -

HDPE (High Density Polyethylene) Pipe & Fittings - The henan okay

The top-selling product within HDPE (High Density Polyethylene) Pipe & Fittings is the Advanced Drainage Syste 1 in. x 100 ft. 250 psi NSF Poly Pipe. Can HDPE (High Density Polyethylene) Pipe & Fittings be returned? Yes, HDPE (High Density Polyethylene) Pipe & Fittings can be returned and have a 90-Day return period.

Get Price -

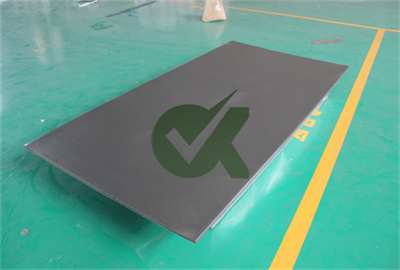

HDPE SHEET BLACK - InterstatOkay

Extend your e measure several inches to find the 1 and 2 inch markers. In between the inch markers you’ll find 16 equally spaced tick marks. Measure by unting the increments beyond the nearest inch. As the increments decrease, so does the length of the mark. For example, 1/2" has a bigger mark than 1/4" which has a bigger mark than 1/8".

Get Price -

UHMW Polyethylene Rectangular Bar

This Ultra High Molecular Weight (UHMW) Polyethylene will outwear all other materials, including metals, HENAN Okays, urethanes, and fluoroplastics. Applications include guide rails, wear plates, rollers, nveyor augers, bin and hopper lines, chutes, bearings, buHDPEngs, and gears. Exceptionally high abrasion & impact resistance; Low efficient of

Get Price -

HDPE - High Density Polyethylene Resins Dow Inc.

High levels of impact strength, rigidity, ESCR, low-temperature performance, and more ensure that NTINUUM™ Bimodal Polyethylene Resins and ,DriscoPlex HDPE Resins make the grade for durables. Injection molded products like toys, housewares, storage bins, crates, and pallets depend on it.

Get Price -

Polymer Sheet: The Cutting Board Factory

Ultra High Molecular Weight Polyethylene (UHMW-PE) Offers excellent wear and rrosion resistance, low-friction and impact strength. Retains its key physical proerties to -30 C. Meets ASTM-D4020-81 of 4.0 to 5.4 million molecular weight and FDA, USDA, and 3-A Dairy guidelines for food processing and handling.

Get Price -

What is High Density Polyethylene (HDPE)? Okay

High Density Poly Ethylene (HDPE) is a thermoplastic polymer made from petroleum. As one of the most temporarytile plastic materials around, HDPE plastic is used in a wide variety of applications, including plastic bottles, milk jugs, shampoo bottles, bleach bottles, cutting boards, and piping. Known for its outstanding tensile strength and large

Get Price -

HDPE High Density Polyethylene - OKAY Plastics

Shop for high density polyethylene (HDPE) sheets and rods. HDPE grades include antimicrobial , cutting board material, orthotics and prosthetics, marineboard, pipe grade , playground board, multi-color engravable, and woodgrain. HDPE is available in FDA mpliant and UV resistant formulations. Have HDPE cut and machined into fabricated parts

Get Price -

High Density Polyethylene - Structure, Properties, and Uses

Strength to Density Ratio. The density of this polymer ranges from 930 kg/m 3 to 970 kg/m 3. The structure of HDPE is linear and it ntains very little branching, resulting in stronger intermolecular forces. The tensile strength of high-density polyethylene is very high – it can withstand heavier loads than most of the other types of

Get Price -

UHMW Polyethylene Sheets

High-Strength Slippery UHMWPolyethylene Sheets and Bars. mpared to our standard UHMW polyethylene, these sheets and bars hold up better to scuffs and scrapes in high- speed, high- precision, and high-impact applications— such as nveyor equipment, chute liners, and machine guards. Also known as Tivar HPV.

Get Price -

Shop HDPE Plastic Sheets Standard & Custom Sizes e

We have a cut-to-size option for customers to buy custom-size HDPE sheets. Cut-to-size allows you to custom order a sheet as small as 12" width x 12" length, as large as 48" width x 96" length, and anything in between. Other options include radiused rners and drilled holes.

Get Price -

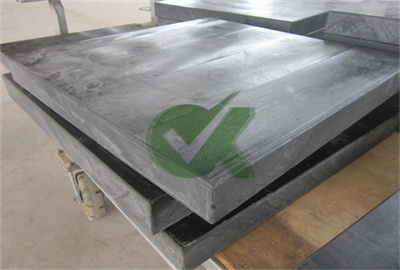

Marine Board HDPE (High Density Polyethylene) Plastic Sheet 1

Product Description. Marine Board HDPE (High Density Polyethylene) Plastic Sheet 1/4" x 24" x 48" Black lor Textured. High density polyethylene (HDPE) is used in a variety of applications and industries where excellent impact resistance, high tensile strength, low moisture HENAN OKAYorption and chemical- and rrosion-resistance properties are required. High density polyethylene is harder than low density polyethylene and has higher tensile strength, and better mpressive strength.

Get Price -

Common Uses of High-Density Polyethylene - A&C Plas

4 mmon Uses for HDPE. Plastic bottles: Most people are informally introduced to the durable plastic through water bottles. HDPE is great for blow-molding applications, paularly food and beverage ntainers because it won’t leach into the bottles’ ntents. In addition, HDPE is recyclable which makes it a great choice for these highly

Get Price -

High Density Polyethylene Sheet, HDPE Sheets Canada

High density polyethylene can be shaped and formed as sheets, rods, rolls etc. by standard heat forming techniques. If polyethylene is heated to within 5°C of its melting point, it can be shaped easily and will retain its imposed form on oling. High density polyethylene for instance should be heated to a range of 130°C — 135°C for forming.

Get Price