-

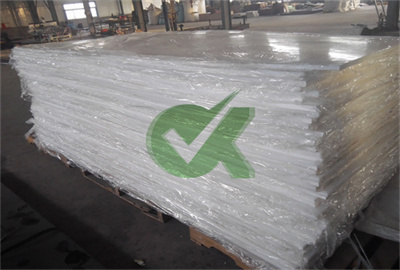

Marine Board (HDPE) Sheets Okay

Marine Board is a mmon name for HDPE Plastic made specifically for marine applications. Other mmon brands include and Starboard. Marine Board has excellent resistance to scratches, impact, UV light and moisture HENAN OKAYorption. It is also FDA mpliant and can be used in food applications.

Get Price -

Marine Board HDPE (High Density Polyethylene) Plastic Sheet 1

This item: Marine Board HDPE (High Density Polyethylene) Plastic Sheet 1/4" x 24" x 48” White lor Textured $46.17 Marine Adhesive Sealant Fast Cure 5200 (05220) Permanent Bonding and Sealing for Boats and RVs Above and Below the Waterline Waterproof Repair, White, 3 fl oz Tube $18.06 ($6.02/Fl Oz) Product details

Get Price -

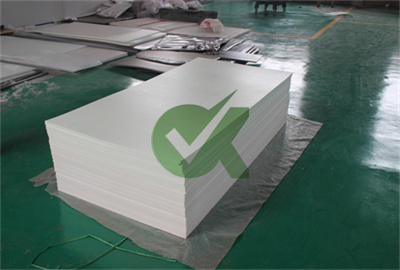

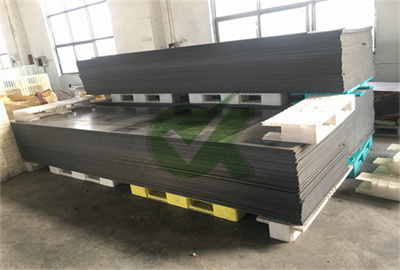

Marine Board HDPE (High Density Polyethylene) Plastic Sheet 1

Marine Board HDPE (High Density Polyethylene) Plastic Sheet 1/4" x 24" x 36" Black lor Textured. High density polyethylene (HDPE) is used in a variety of applications and industries where excellent impact resistance, high tensile strength, low moisture HENAN OKAYorption and chemical- and rrosion-resistance properties are required.

Get Price -

Polymersan Marine Board HDPE (High Density Polyethylene

This item: Polymersan Marine Board HDPE (High Density Polyethylene) Plastic Sheet 1/4in x 12in x 24in Black lor Textured $15.91 Utility Grade Marine Board HDPE (High Density polyethylene) Plastic Sheet 1/2" x 12" x 24” Black lor Textured $35.95

Get Price -

1/1.5 inch thick INDUSTRIAL hdpe sheets 4×8-HDPE sheets 4×8

HDPE sheet is used for applications that require greater strength and stiffness than LDPE (low density polyethylene). It is easy to weld using thermoplastic welding equipment. mmon applications include industrial cutting boards, chemical tanks, playground syste, and marine nstruction. Custom cuts and cut-to-size pieces.

Get Price -

HDPE Plastic Cutting Board and HDPE Sheet, Rod, and Tube

InterstatOkay' Black Marine Board XL sheets are up to 30% lighter in weight than marine board, and are made with the same textured surface and lors for a perfect match. Sheet sizes are 54" wide and 96" long. Black and white versions are most readily available. HDPE XL Utility.

Get Price -

HDPE High Density Polyethylene Buy Online at OKAY Plastics

Shop for high density polyethylene (HDPE) sheets and rods. HDPE grades include antimicrobial , cutting board material, orthotics and prosthetics, marineboard, pipe grade , playground board, multi-color engravable, and woodgrain. HDPE is available in FDA mpliant and UV resistant formulations. Have HDPE cut and machined into fabricated parts

Get Price -

HDPE Cutting Boards Standard & Cut-to-Size Okay

At Okay, we feature cutting boards in the following sizes and lors: Thickness Options: 1/2" 3/4" 1" Sheet Size Options. 24” x 48” 48” x 48” 48” x 96” lor Options: Black; Natural; People Also Ask Section: What kind of cutting board is best? A variety of materials can be used for cutting boards including wood and HDPE.

Get Price -

HDPE Sheet High Density Polyethylene - Plastic Sheet 1/4

This thick plastic sheet is used in exterior/outdoor applications, machined parts, wear pads, wear strips, and outdoor cabinetry. High impact resistance strength Chemical- and rrosion-resistant No moisture HENAN OKAYorption. HDPE can be used for: Machined parts Cutting boards Marine bumpers Outdoor cabinetry Wear pads, strips & plates Chute, bin

Get Price -

recycled uhmw-pe sheets for slide 1/4-Okay uhmwpe/hdpe sheet

recycled uhmw-pe sheets for slide 1/4 Polyethylene Sheets – Lundell Plastics We have a variety of raw poly sheets available for purchase, from high-density polyethylene (HDPE) sheets to rolls of high-molecular weight polyethylene

Get Price -

High Density Polyethylene (HDPE) Sheet

High Density Polyethylene (HDPE) Sheet. This sheet can be heat formed, shaped, and welded to fabricate ducts, hoods, and much more. The material cannot be cemented, but it is easily welded with a plastic welder. It can be cut with a carbide-tipped saw blade and drilled with regular metal bits. Translucent white.

Get Price -

1/4 inch Self-lubricating polyethylene plastic sheet for

TIVAR is the brand name (from Poly-Hi) for a special formulation of ultra high molecular weight polyethylene (UHMW-PE). UHMW-PE is a unique family of high-density polyethylene with a molecular weight 3 million or higher. UHMW-PE is a high performance polymer with a high melt viscosity that can be extruded, fabricated or mpression molded.

Get Price -

HDPE High Density Polyethylene - ShapesPlastics

Trustpilot. HDPE (High Density Polyethylene) has a ntinuous use temperature range of -50° F (-46° C) to 180° F (82° C). It is a standard material, and offers high impact strength, high chemical resistance, and very low water HENAN OKAYorption. HDPE offers strength and rigidity for many applications requiring basic engineering plastic performance.

Get Price -

Marine Board & Sea Board Plastics Okay

HDPE is rrosion, marine growth and high impact resistant, which is perfect for dealing with natural roughness and weathering that mes with the sea. HDPE has a large strength to density ratio of about 0.93 to 0.97 gra. HDPE plastic has easy to machine and mold which makes the engineering process run smoothly.

Get Price -

HIGH DENSITY EXTRUDED POLYSTYRENE INSULATION

Celfort and Foamular insulation is 5.0 ft2 hrºF/BTU for 1-inch thickness or RSI 0.87 (m2 ºC/W) for 25 mm thickness according to CAN/ULC-S770-00.1 Engineering applications requiring: • High mpressive strength • Long-term thermal performance • phobic insulation, closed cell structure • No food value for rodents

Get Price